Process optimization

Process optimization is done for the existing process or to develop a new process based on industry. To improve efficiency by streamlining operations, reduces costs through minimizing waste and resource use, and enhances product quality by ensuring consistency and reliability. It increases productivity by enabling higher output in less time, improves food safety by strengthening hygiene and traceability, and boosts competitiveness by lowering costs and improving standards. Additionally, it supports sustainability by reducing environmental impact, speeds up time-to-market by shortening production cycles, facilitates innovation by freeing resources for new developments, and ensures regulatory compliance by aligning processes with food safety laws and standards.

Process optimization methods used based on the product process type and industry:

Lean Manufacturing

Eliminates waste to enhance efficiency and productivity.

Six Sigma

Reduces defects through data-driven quality improvement.

Automation & Robotics

Increases precision and efficiency in production.

Process Mapping & Flow Analysis

Visualizes and streamlines operational workflows.

Statistical Process Control (SPC)

Monitors quality using real-time process data.

Computer-Aided Process Simulation

Models and optimizes production systems digitally.

Total Quality Management (TQM)

Promotes continuous quality improvement organization-wide.

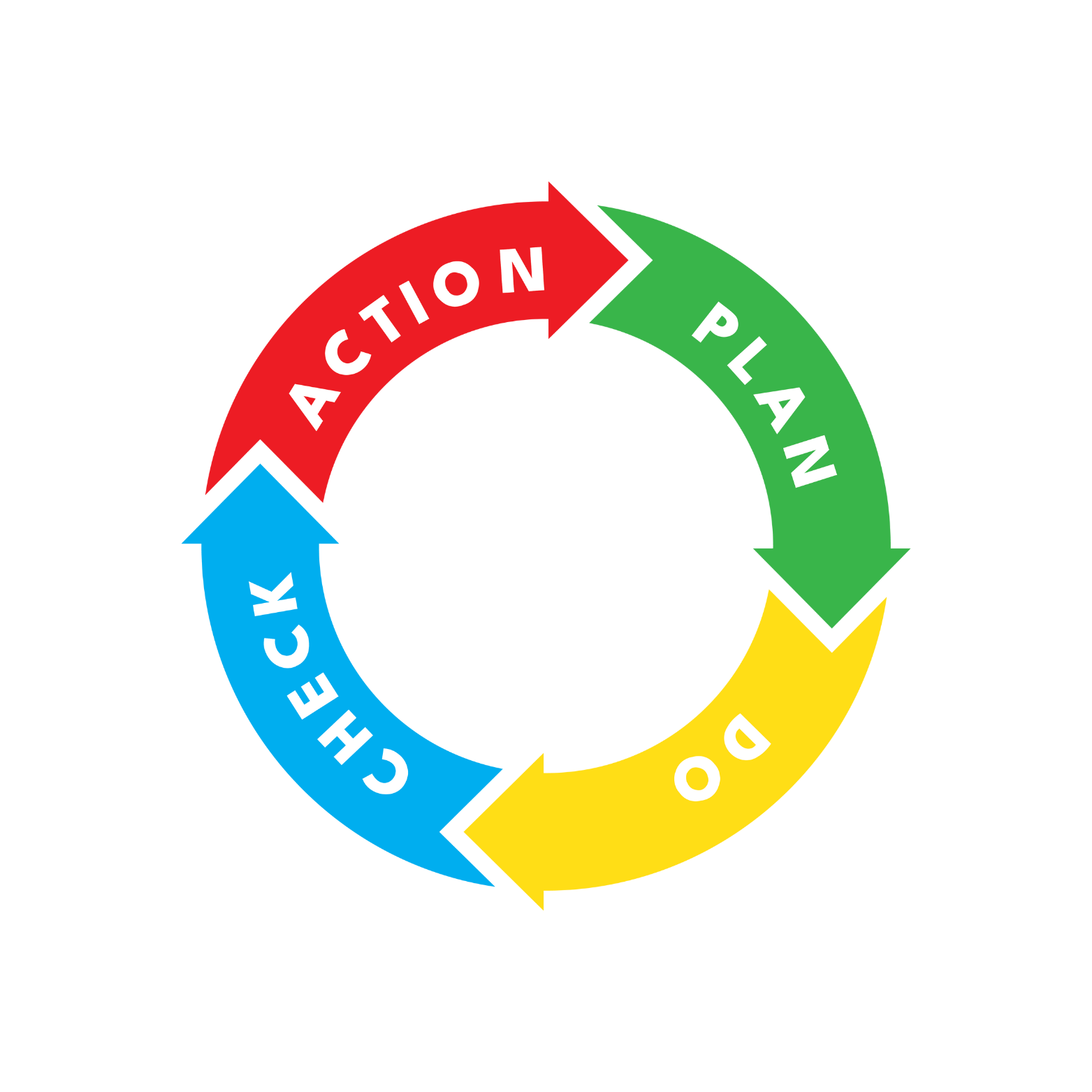

Kaizen (Continuous Improvement)

Encourages small, ongoing changes for better performance.

Energy Optimization

Reduces energy use for cost savings and sustainability.

Supply Chain Optimization

Improves logistics, coordination, and overall efficiency.